SugarLaneDesign manufacturing innovation represents a forward-thinking approach to transforming production processes, blending advanced technology with sustainable practices to enhance efficiency and creativity. Drawing inspiration from platforms like sugarlanedesign.com, which covers trending news on technology and manufacturing, SugarLaneDesign likely focuses on integrating cutting-edge solutions like robotics, automation, and sustainable design into manufacturing. This article explores how SugarLaneDesign drives innovation in manufacturing, offering insights and practical strategies for businesses aiming to modernize their production systems in 2025.

The Essence of SugarLaneDesign Manufacturing Innovation

SugarLaneDesign manufacturing innovation emphasizes leveraging advanced technologies to streamline production while prioritizing sustainability and adaptability. Inspired by industry trends highlighted on sugarlanedesign.com, the approach likely integrates robotics, IoT, and AI to optimize processes, much like the sugar industry’s adoption of energy-efficient systems. By focusing on human-centered design and eco-friendly practices, SugarLaneDesign helps manufacturers reduce costs, improve quality, and meet modern consumer demands for sustainable products, setting a new standard for innovative production.

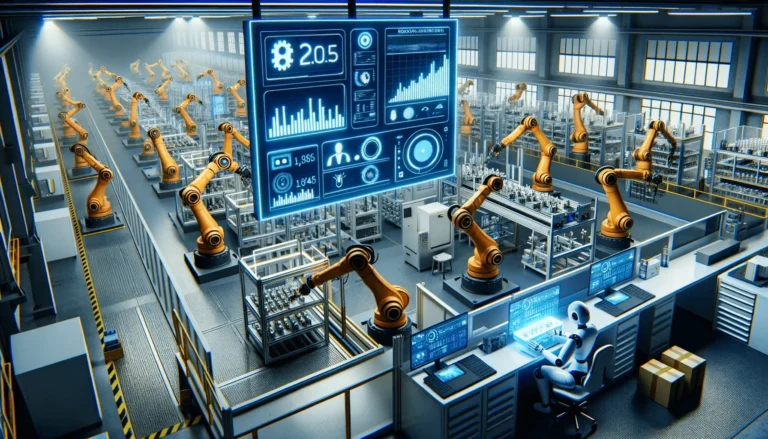

Harnessing Robotics and Automation

A cornerstone of SugarLaneDesign manufacturing innovation is the use of advanced robotics and automation to enhance efficiency. As noted on sugarlanedesign.com, robotics are transforming manufacturing by automating repetitive tasks, improving precision, and reducing labor costs. For example, implementing robotic arms for assembly lines can increase throughput by up to 30%, as seen in automotive manufacturing. Businesses can adopt collaborative robots (cobots) that work alongside humans, ensuring flexibility and safety while boosting productivity in small- to medium-sized enterprises.

Integrating IoT for Smart Manufacturing

Internet of Things (IoT) technology is central to SugarLaneDesign’s vision of smart manufacturing. IoT-enabled devices, such as sensors on production equipment, provide real-time data on machine performance and inventory levels, as highlighted by ABB’s solutions for sugar manufacturing. This allows for predictive maintenance, reducing downtime by up to 20%, and optimizing material use. Manufacturers can start with IoT platforms like Siemens MindSphere to monitor operations, ensuring seamless integration and data-driven decision-making across the production chain.

Adopting Sustainable Production Practices

Sustainability is a key focus of SugarLaneDesign manufacturing innovation, aligning with global trends toward eco-friendly production. Inspired by the sugar industry’s shift to renewable energy and water-saving technologies, businesses can implement solar-powered systems or efficient irrigation to reduce environmental impact, as noted by atharvasolutions.co.in. Using biodegradable materials or recycling byproducts, like sugarcane biomass for biofuels, enhances sustainability while meeting consumer demand for green products, boosting brand reputation and compliance with regulations.

Leveraging Design Thinking for Innovation

Drawing from the SUGAR Network’s approach, SugarLaneDesign incorporates design thinking to solve manufacturing challenges creatively. This human-centered methodology, as described on sugar-network.org, involves prototyping and testing solutions to meet end-user needs. For instance, designing ergonomic tools or intuitive machine interfaces can improve worker efficiency and reduce errors. Manufacturers can adopt design thinking workshops, collaborating with interdisciplinary teams to develop innovative products, like the gamified ADAS system for driver assistance, enhancing user engagement and functionality.

Streamlining Supply Chains with Digital Tools

SugarLaneDesign manufacturing innovation emphasizes digital tools to optimize supply chains. Platforms like Auto Integrate, which streamline repair orders, inspire solutions for real-time inventory tracking and supplier coordination. By adopting ERP systems tailored for manufacturing, such as those used in sugar production, businesses can reduce inventory costs and improve traceability. Start with cloud-based software like SAP Business One to integrate procurement, production, and distribution, ensuring agility in a competitive market.

Overcoming Manufacturing Challenges

Modern manufacturing faces challenges like high energy costs and regulatory compliance. SugarLaneDesign addresses these by promoting energy-efficient processes, such as advanced crystallization techniques that reduce waste, as seen in sugar industry innovations. To navigate regulations, implement automated compliance tracking systems to ensure adherence to standards like ISO 14001. Regular training on new technologies, inspired by SUGAR Network’s educational approach, equips teams to adapt to evolving industry demands, minimizing disruptions.

The Future of SugarLaneDesign Manufacturing Innovation

Looking ahead, SugarLaneDesign manufacturing innovation is poised to embrace AI and biotechnology, mirroring trends in the sugar industry where AI optimizes yields and biofuels drive sustainability. Future advancements may include AI-driven quality control or 3D printing for rapid prototyping, reducing production timelines. By fostering partnerships with academic networks like SUGAR, SugarLaneDesign can stay at the forefront of innovation, developing solutions that are both cutting-edge and market-responsive, ensuring long-term competitiveness.

Conclusion: Innovate with SugarLaneDesign

SugarLaneDesign manufacturing innovation offers a blueprint for modernizing production through robotics, IoT, sustainability, and design thinking. By adopting these strategies, businesses can enhance efficiency, reduce environmental impact, and meet evolving market needs. Visit sugarlanedesign.com for more insights on manufacturing trends, and start transforming your production processes with innovative, sustainable solutions today.

Read More: